August 2005 -- December 2006

This page shows several improvised machines for weaving Visco-type pyrotechnic fuse. It also gathers links to photos documenting older commercial machines. Visco was one brand of such machines, which is the name now commonly used for the generic fuse product.

Visco fuse consists of an inner core of finely granulated black powder, contained in a spiral-wound wrap of cotton threads, which in turn is surround by another spiral wrap in the opposite winding direction. Tracer threads may be entrained in the powder core. This powder-cored twine is then coated with colored nitrocellulose lacquer to bind, stiffen, strengthen, and waterproof the fuse with a combustible coating. Typical diameters are 1/16, 3/32, or 1/8 inch, or 1 or 2 mm. Visco fuse is also known as cannon fuse or safety fuse. Japanese time fuse (1/4 inch diameter) is a similar item used for time delays in pyrotechnic shell building, but incorporates an additional thick layer of asphaltum.

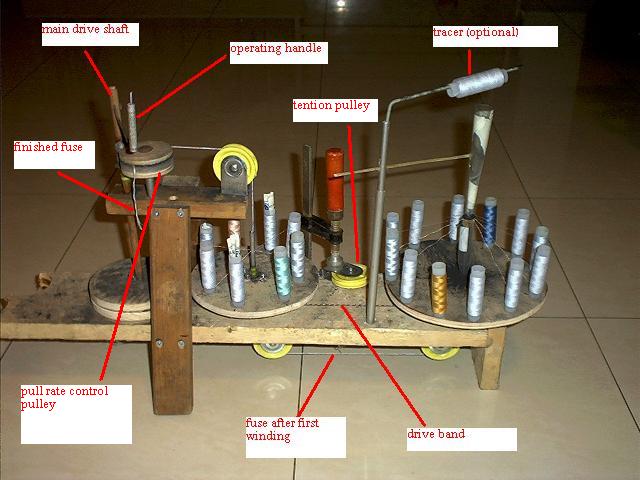

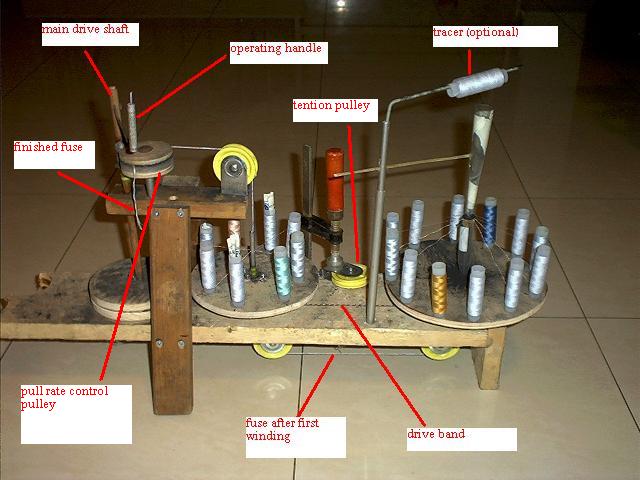

The first machine is by "yuvyuv" (email) posting on the newsgroup rec.pyrotechnics (as "Yuv"). See the original thread [groups.google.com] discussing the machine, and a follow-up thread which includes Yuv's description of how the machine works.

General View

Side View

First Die

Finished Fuse

Fuse Closeup

These nine pages of drawings [215 KB PDF file] show a different design and CAD model by Daniel Turner.

The model is missing critical items like the funnel and spinneret, and thus are not detailed enough for fabrication.

These nine pages of drawings [215 KB PDF file] show a different design and CAD model by Daniel Turner.

The model is missing critical items like the funnel and spinneret, and thus are not detailed enough for fabrication.

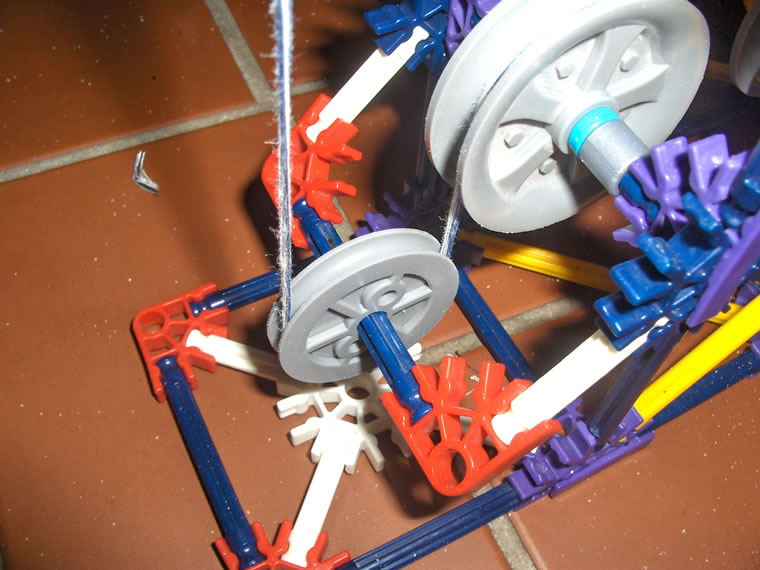

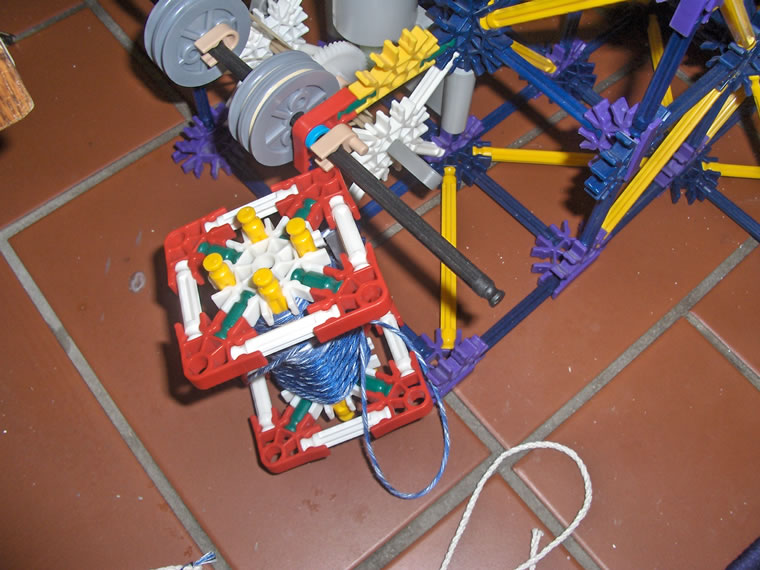

Ryan Turner created an fuse-weaving machine from K'NEX (http://www.knex.com/) construction toys. He described this in a rec.pyrotechnics thread thread [groups.google.com], and offered the following photos and descriptions showing the mechanism operating with an inert core substance (table sugar):

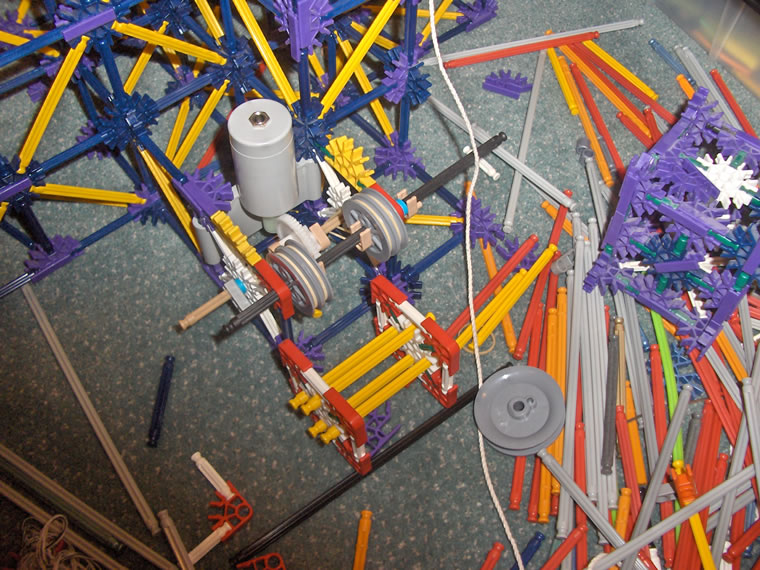

Overview

This is an overview of the entire machine. It has two rotating disks

with eight rolls of thread a piece. They are positioned vertically.

This is an overview of the entire machine. It has two rotating disks

with eight rolls of thread a piece. They are positioned vertically.

Second overview

Second overview.

Second overview.

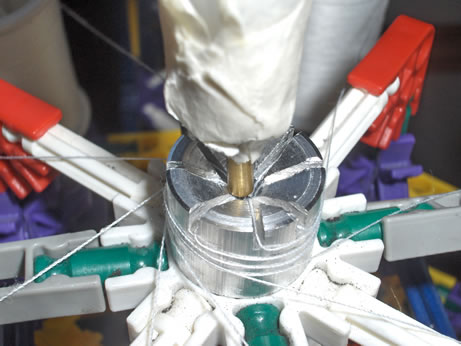

White die

The "White" die (named because the first thread is white) is where it

happens. It took two tries to get a working die, this is really the

only important part. The brass tubing needs to be lowered as far as

possible without jamming up the white threads wrapping around it.

Currently about three quarters of the sugar that leaves the funnel gets

woven into the fuse.

The "White" die (named because the first thread is white) is where it

happens. It took two tries to get a working die, this is really the

only important part. The brass tubing needs to be lowered as far as

possible without jamming up the white threads wrapping around it.

Currently about three quarters of the sugar that leaves the funnel gets

woven into the fuse.

White die, second view

This view is a bit clearer. Its pretty much magic that it works, I

never expected it to weave in so easily. It doesn't look like its

possible for thread to just wrap around a powder but it works!

This view is a bit clearer. Its pretty much magic that it works, I

never expected it to weave in so easily. It doesn't look like its

possible for thread to just wrap around a powder but it works!

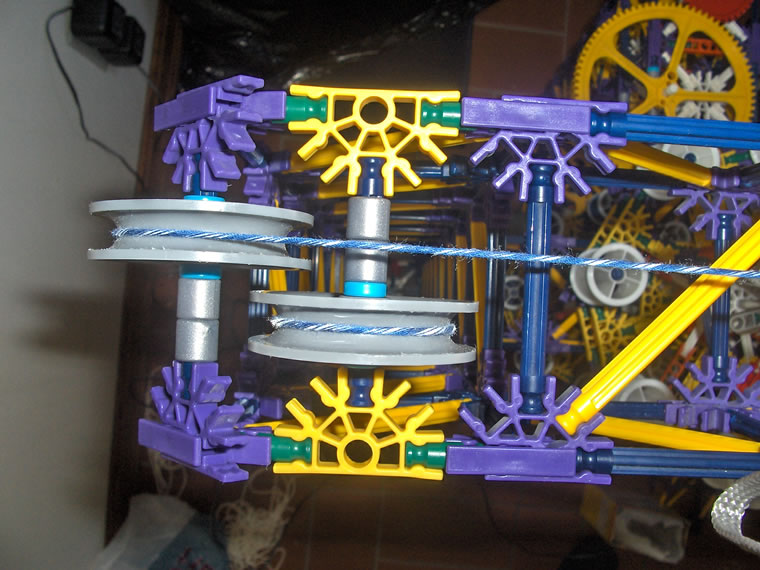

Blue die

Here is the second die (the "blue" one). The machine isn't operating

when I took these pictures so there is no sugar. The blue die isn't

really that important.

Here is the second die (the "blue" one). The machine isn't operating

when I took these pictures so there is no sugar. The blue die isn't

really that important.

Comparison, unfilled vs filled

This is a comparison of the fuse with no sugar inside (left one) and

fuse with sugar inside (right one).

As you can see, the sugar can work its way out (which is why I need

thicker thread) but it works beautifully.

This is a comparison of the fuse with no sugar inside (left one) and

fuse with sugar inside (right one).

As you can see, the sugar can work its way out (which is why I need

thicker thread) but it works beautifully.

Completed fuse

Just a close up of the fuse. The sugar on the ground didn't leak from

the fuse, any sugar that doesn't get woven into the machine hits the

spinning disks and flies everywhere. I'll have to use the machine

outside.

Just a close up of the fuse. The sugar on the ground didn't leak from

the fuse, any sugar that doesn't get woven into the machine hits the

spinning disks and flies everywhere. I'll have to use the machine

outside.

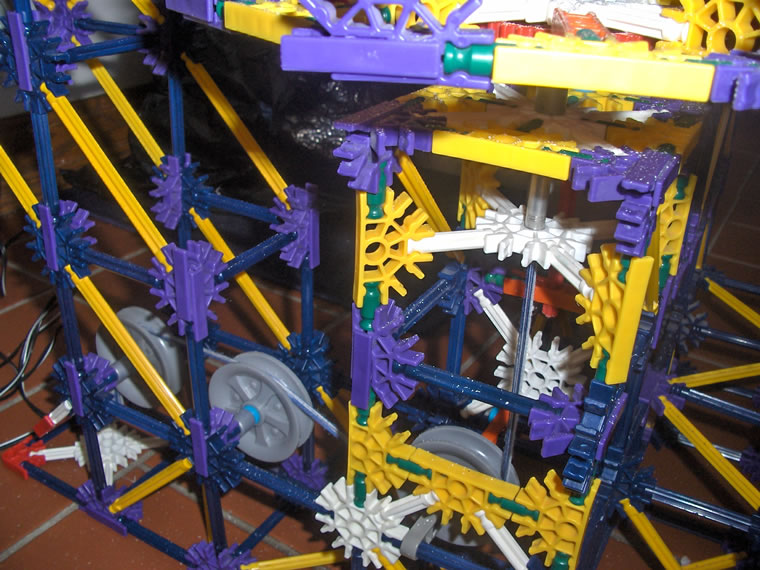

Version 2

This K'NEX design was later updated to a second version.

The main additions are a drying tunnel, lacquer applicator and a

better reel where it winds up.

This K'NEX design was later updated to a second version.

The main additions are a drying tunnel, lacquer applicator and a

better reel where it winds up.

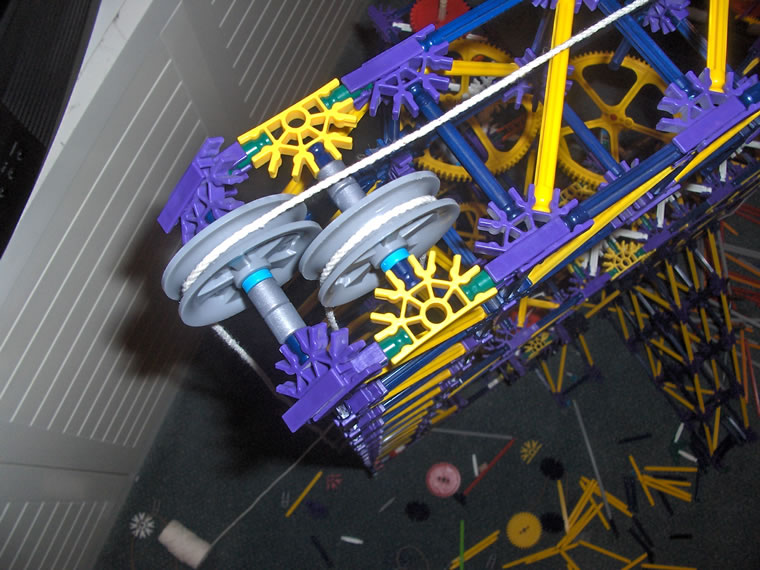

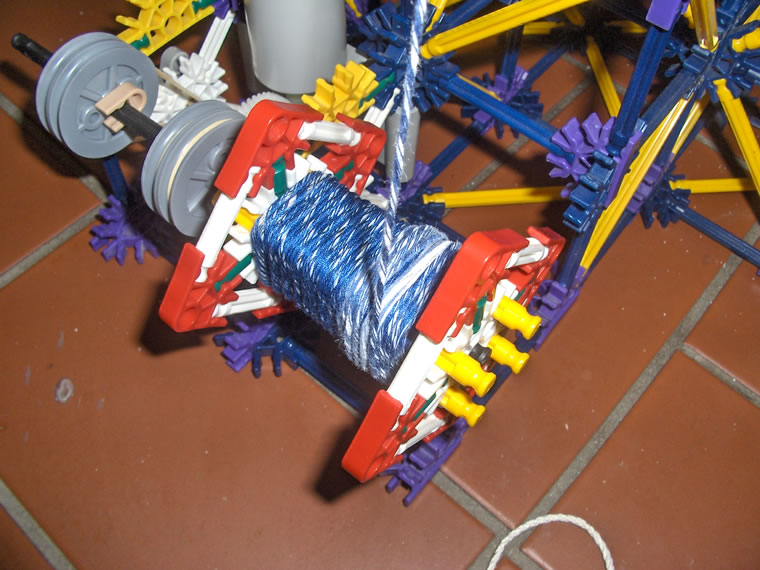

Wind-up reel

The finished fuse winds up on this reel. It is now powered by a

separate motor. I am guessing it can hold around 30m of fuse. Once

your finished, the reel just slides off and you can unwind the fuse

from it.

The finished fuse winds up on this reel. It is now powered by a

separate motor. I am guessing it can hold around 30m of fuse. Once

your finished, the reel just slides off and you can unwind the fuse

from it.

Drying tunnel

This is the drying tunnel. The fuse takes three passes through it and

I'm guessing its about a meter high.

This is the drying tunnel. The fuse takes three passes through it and

I'm guessing its about a meter high.

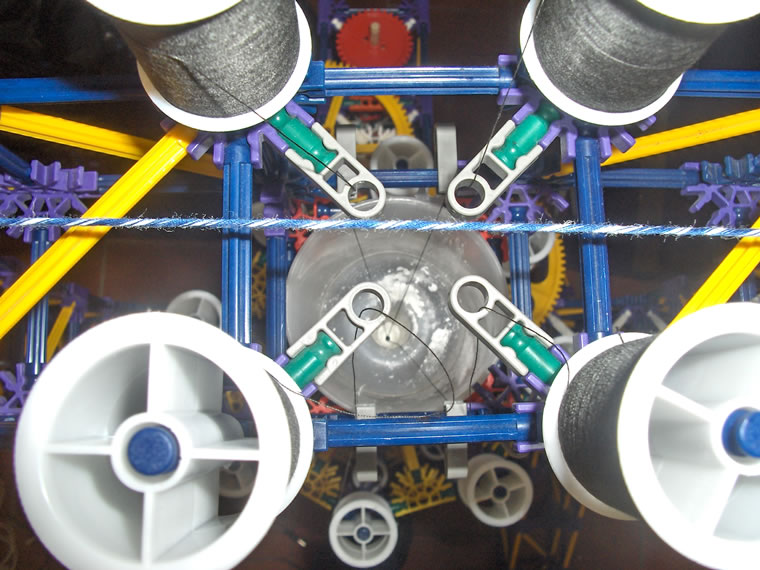

Tracer threads

And here is a bit of a play by play of how the powder becomes

a fuse core.

The powder is loaded into the funnel and gets pulled down by the

four tracer threads.

And here is a bit of a play by play of how the powder becomes

a fuse core.

The powder is loaded into the funnel and gets pulled down by the

four tracer threads.

First (white) threads

The powder gets wrapped by the first threads.

The powder gets wrapped by the first threads.

Second (blue) threads

The powder, now wrapped in a core surrounded by white threads, gets wrapped in the

opposite direction by blue threads (The machine is off so the threads

aren't twisted).

The powder, now wrapped in a core surrounded by white threads, gets wrapped in the

opposite direction by blue threads (The machine is off so the threads

aren't twisted).

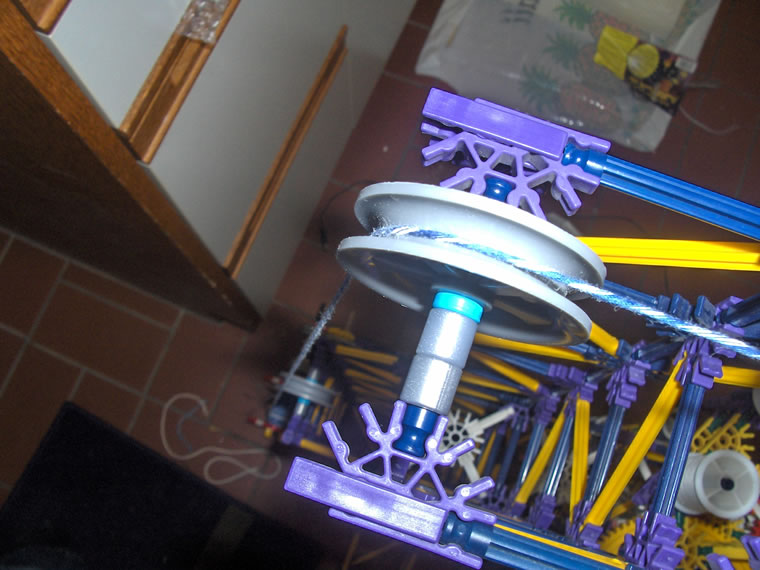

Path to lacquer cup

The fuse goes through a series of pulleys to bring it to ...

The fuse goes through a series of pulleys to bring it to ...

Lacquer cup

The lacquer will be in a small cup/dish under the small pulley.

The lacquer will be in a small cup/dish under the small pulley.

Drying tunnel

The fuse spends three passes drying.

The fuse spends three passes drying.

And goes across the machine, going down on the other side (add about

one and a half meters to the drying time).

And goes across the machine, going down on the other side (add about

one and a half meters to the drying time).

The fuse spools up onto this thingy.

The fuse spools up onto this thingy.

Which then slides off.

Which then slides off.

And here are the results (no lacquer). An empty fuse is on the right, the fuse with stuff in it is on the left.

Sugar

The sugar is, as usual, working great. This picture is nice because

near the bottom you can see the sugar trapped under a lattice of

threads.

The sugar is, as usual, working great. This picture is nice because

near the bottom you can see the sugar trapped under a lattice of

threads.

Corn starch

This one is a little less inspiring however it still worked. Most of

the cornstarch simply coated the threads however there is a core of

pure cornstarch in the center.

This one is a little less inspiring however it still worked. Most of

the cornstarch simply coated the threads however there is a core of

pure cornstarch in the center.

Some other photos of Visco-type machines I've found on the Web: http://www.fireworkstown.com/Product/photo/2005218153180.jpg, http://www.fireworkstown.com/Product/photo/2005218150560.jpg. These links seem to have gone stale, so try the historical copies at archive.org: first photo, second photo,